Roll Formed Panels

Panels offer wide coverage to an area with a thin metal surface. Applications include roofs, walls, side panels, shelters and the like. Roll formed roof, wall and floor panels add style and strength to commercial & industrial buildings, recreational vehicles, manufactured homes, railroad cars, agricultural vehicles and equipment, noise barriers, fencing, siding and decks. Roll-formed panels are an excellent choice where insulation, temperature control, sound dampening and acoustics are a concern. We designed our panels with design, value and quality in mind.

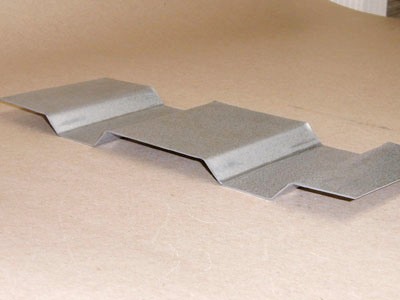

- P-101

0.5" x 14", P-101 20-gauge roll formed forage wagon 2 rib panel. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

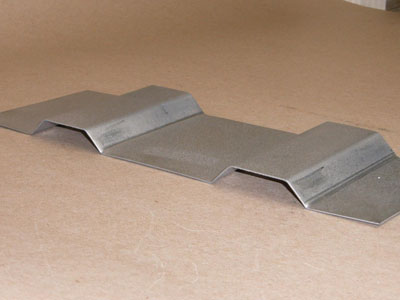

- P-101

0.5" x 14", P-101 20-gauge roll formed forage wagon 2 rib panel shown stacked in a bundle. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

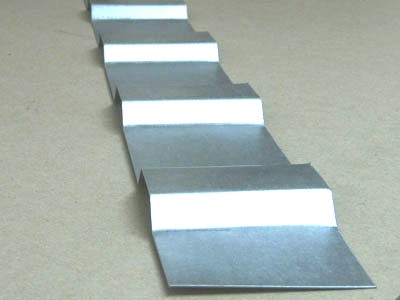

- P-101

0.5" x 14", P-101 20-gauge roll formed forage wagon 2 rib panel shown in reverse orientation. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-102

0.5" x 25.5", P-102 20-gauge roll formed forage wagon 4 rib panel. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-103

0.5" x 41", P-103 20-gauge roll formed forage wagon 6 rib panel. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application, but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-103

0.5" x 41", P-103 20-gauge roll formed forage wagon 6 Rib Panel bundle. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application, but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-103

0.5" x 41", P-103 20-gauge roll formed forage wagon 6 rib panel. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a side wall in a forage wagon application but has also been put to use in residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-104

3.5" x 19.5", P-104 18-gauge roll formed galvanized playground slide. This panel can be roll formed in a variety of materials, usually hot dipped galvanized steel, aluminized or galvalume, for corrosion protection. It is commonly used as a slide in children's playground set but has also been put to use in other residential and commercial construction projects. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-106

0.875" x 38", P-106 26 to 28-gauge roll formed pre-painted agricultural 38-inch-wide panel. The most common gauge steel panels used are 29 gauge. The thicker 26-gauge upgrade) is typically used on commercial structures and places with unusual requirements. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.

- P-107

24 1" x 10.5" Gauge Galvalume Panel. This 26-gauge panel is roll formed in galvalume coated steel and is appropriate for outdoor applications. Slots are available for mounting or connecting to other components. It has applications in the construction and solar industries. As a coil-based process, economical production quantities begin around 5,000 lineal feet. Custom lengths are available to meet OEM requirements.